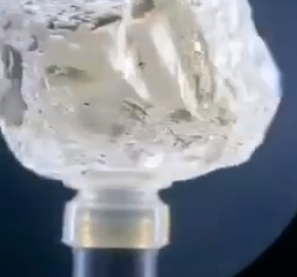

1. the overall naked eye is rough stone crystal shape, rough stone about 30 carats, the quality of the color of the whole stone from the color level above is very white, high color level is probably DEF color level.

2. Observe the distribution of defects of rough diamond stones under the microscope, and mark them with a pen to prepare for preliminary polishing.

3. Preliminary diamond cutting with laser cutting instrument, remove the natural weathered skin and obvious defects on the surface. The preliminary design of the cutting and grinding shape is round, which can take care of the most.

4. The basic shape of the round diamond is cut and ground for the second time, and then the diamond is finely polished by hand, with 57 facets finely cut and ground one by one.

5. the final cut into the finished product, is a 10-carat diamond.

Round diamonds are also very expensive to cut, with only 40 to 50 percent yield. Shaped diamonds have a higher yield, usually 60 to 70 percent. This is one of the reasons why shaped diamonds are cheaper than round diamonds, but round diamonds show the best brightness and color of a diamond.